Bubbles & Foams

Measure the bubble size in gas dispersions and analyze foam characteristics in real time

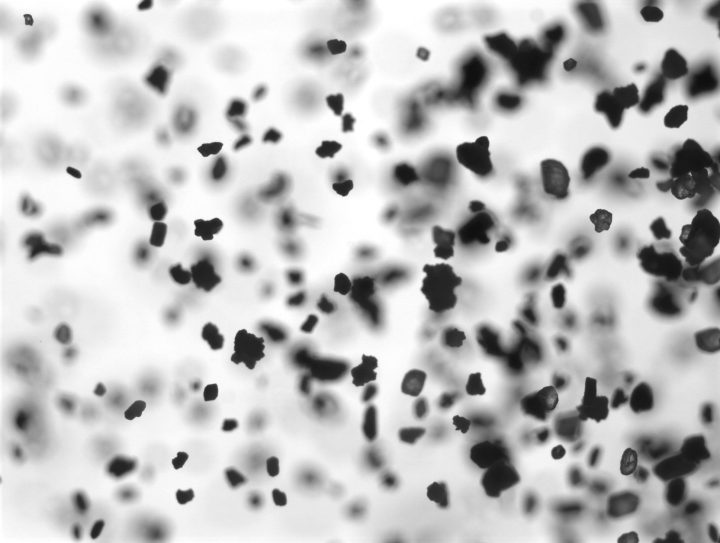

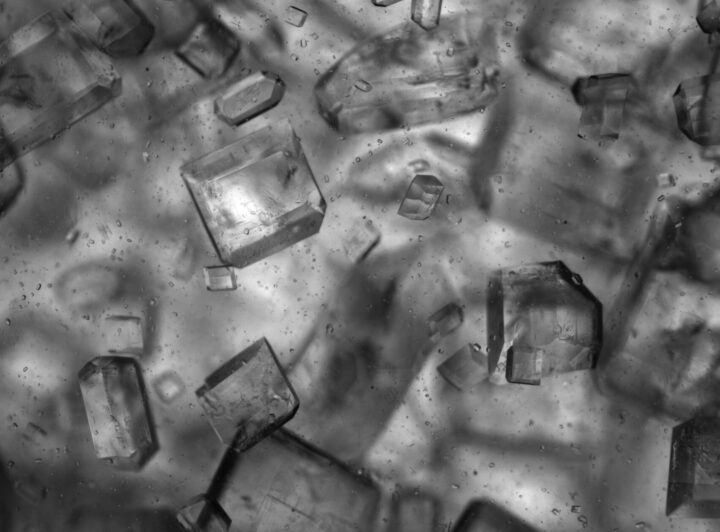

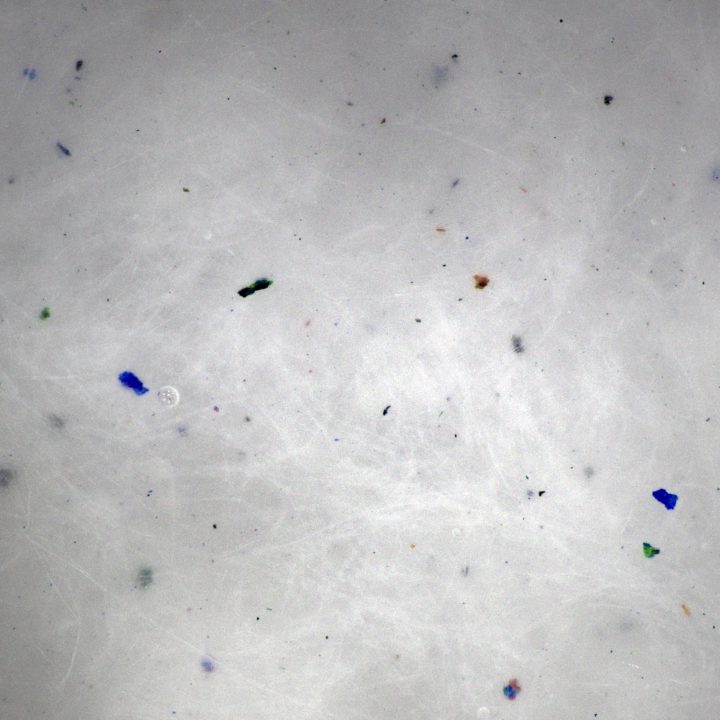

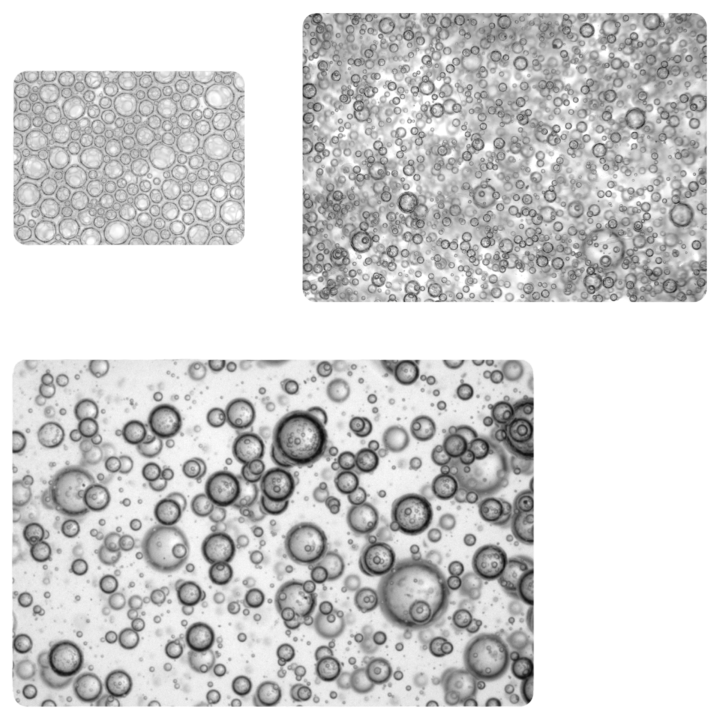

Analyze gas dispersions in real time with Pixact Bubble Monitoring

Gas dispersions, such as bubble suspensions and foams, are commonly used in coating, forming, flotation and mass transfer processes. Pixact Bubble Monitoring (PBM) technology is designed for the inline analysis of gas bubbles. The PBM technology can be used for measuring both foams with high gas content and bubble suspensions with lower gas content. The PBM technology combines inline process microscopy with advanced image analysis techniques. Measurement data produced by PBM helps you to optimize, control and troubleshoot your gas removal and gas dispersion operations and foam processes efficiently.

Results

Microscope-quality live view of the gas dispersion provides valuable visual information of the process. The proprietary image analysis algorithms of the measurement system detect bubbles in the image data and produce detailed real-time numerical information on their characteristics and other suspension properties.

Measurement results produced by PBM include

- Bubble size distribution and related statistics, such as Arithmetic, Sauter and volumetric mean diameter, and percentiles of cumulative distribution (D10, D50, D90, etc.)

- Bubble count

- Bubble concentration / foam density

- Bubble flow velocity

Discover solutions for Bubbles & Foams application

Explore our advanced solutions for real-time analysis. From the Pixcell flow-through cuvette to the Pixscope probe, find the perfect product for your needs.