Monitoring of a mineral flotation cell

Motivation

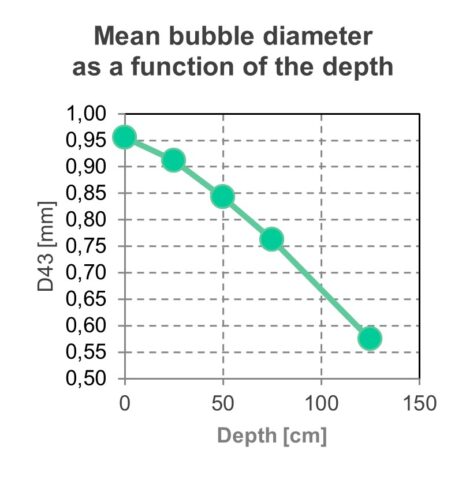

The performance of a flotation process is determined by the separation efficiency of the valuable component and product purity. Performance depends on bubble size distribution, holdup and superficial gas velocity.

Implementation

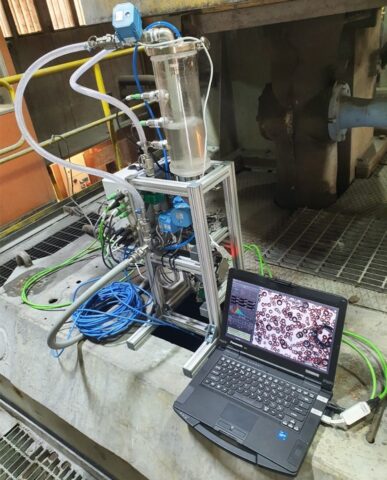

A custom Pixact Bubble Monitoring (PBM) system was developed to measure these flotation performance quantities in a production-scale mineral flotation cell.

Benefits

PBM system is a great tool for process optimization. Mixing has the greatest effect on bubble size: increased mixing decreases bubble size whereas increased air feed increases bubble size. Trials also showed that bubble size correlated strongly with the feed sludge. High sludge density reduced flow turbulence in the cell and therefore weakened the gas dispersion leading to an increase in bubble size.

Process parameters

| Process | Flotation in a gold mine |

| Bubble size distribution | 0.2…5mm |

| Solids concentration | 5 w-% |

| Temperature | 10-20°C |

| Pressure | Atm |