Crystals

Monitor crystal nucleation, growth, and morphology in both continuous and batch processes in real time

Optimize your process with Pixact Crystallization Monitoring

Crystallization is a separation and purification technique widely used in the process industry.

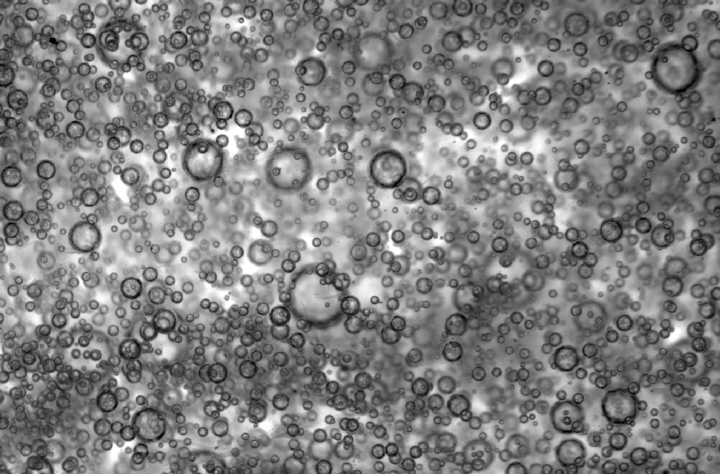

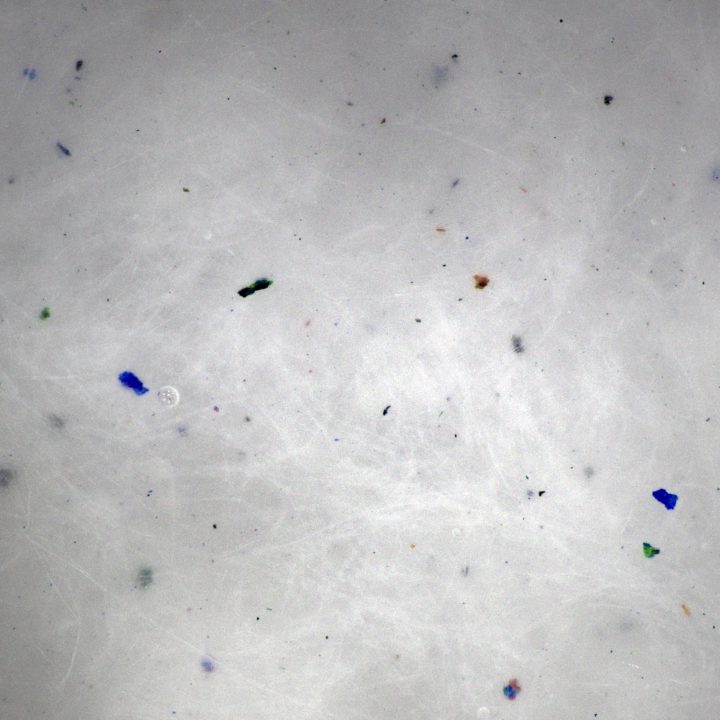

Pixact Crystallization Monitoring (PCM) technology is designed for the inline analysis and control of batch and continuous crystallization processes. The technology combines inline process microscopy with advanced image analysis techniques. PCM offers high-quality live view and real-time crystal analysis even in high color and high concentration crystal slurries.

Measurement data produced by PCM helps you to optimize, control and troubleshoot your crystallization process efficiently. With PCM you can increase the yield and capacity of your process and minimize quality variations in the final product.

Results

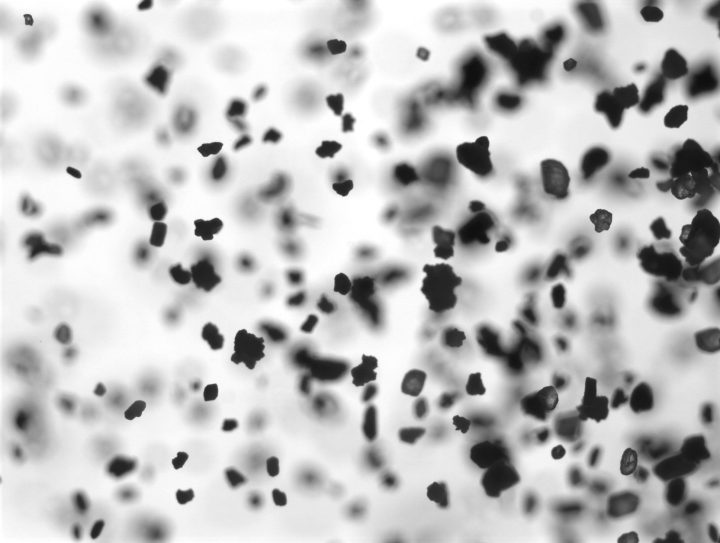

PCM technology provides a live camera view of the process and detailed real-time measurement data on crystal characteristics, such as size distribution, morphology and concentration.

The crystal size distribution can be processed further to calculate mean size and standard deviation, percentiles of cumulative distribution (D10, D50, D90, etc.) and fractions of fine and coarse crystals, and much more.

The measurement results produced by PCM include

- Crystal size distribution and related statistics

- Crystal growth rate

- Crystal morphology (aspect ratio, etc.)

- Number of crystals in the measurement volume

- Suspension flowability

Discover solutions for Crystals application

Explore our advanced solutions for real-time analysis. From the Pixcell flow-through cuvette to the Pixscope probe, find the perfect product for your needs.