Optimization of gas dispersion in delignification

Motivation

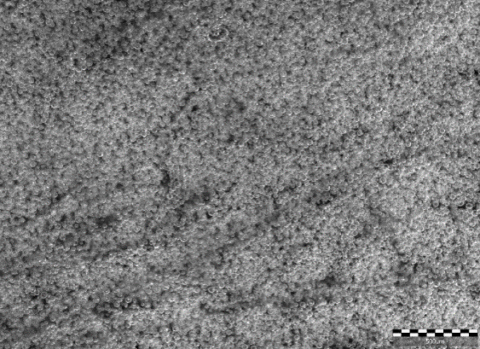

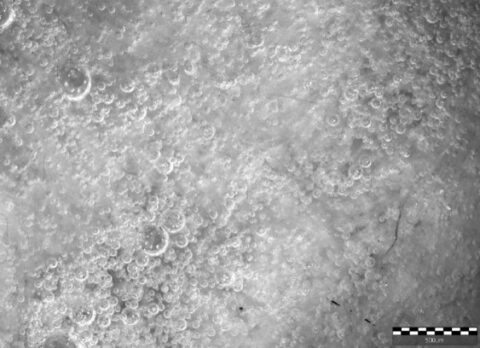

Oxygen delignification is used in pulp mills for lignin removal. The quality of oxygen dispersion (bubble size distribution and concentration) is crucial for determining the interfacial surface area and oxygen solubility.

Implementation

A Pixact Bubble Monitoring (PBM) system is installed on the bottom of an oxygen delignification tower (inlet) and another on the top (outlet). The systems are used to continuously monitor gas dispersion. Comparing the results from the inlet and outlet allows for the estimation of gas uptake.

Benefits

The measurement system helps to optimize and control the process by showing how changes in key process parameters affect gas dispersion in real time.

Process parameters

| Process | Pulp delignification |

| Bubble size distribution | 20…500µm |

| Solids concentration | 2-7 w-% |

| Temperature | 90°C |

| Pressure | Up to 10 Bar |

| Other remarks | pH 10 |