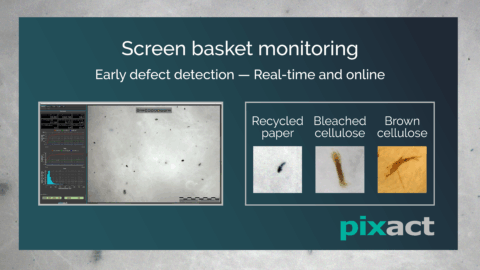

Screen basket monitoring

Motivation

Many screen baskets are used in stock preparation to clean the raw material and remove foreign particles. Depending on the raw material and target quality, certain shapes and size classes must be removed. There is usually an accept stream. This is monitored with the Pixact system in order to detect defects in the screen baskets immediately and gradually.

Implementation

A camera is installed in the acceptance stream downstream of the sorting stage and continuously measures the screening. The values are transferred to the process control system in real time. As soon as size classes are detected that indicate a defect in the screen baskets, an alarm is triggered. The material flow of the individual screen baskets can be directed to the Pixact camera by means of a manual switch. This allows the defective basket to be identified in the shortest possible time.

Benefits

By recognizing a defect at an early stage, maintenance work can be planned directly and specifically. Sampling of the individual units is not necessary. In the event of gradual wear, the replacement can be scheduled into planned downtimes. All in all, this saves a great deal of time and therefore maintenance budget. In addition, a constant quality of the semi-finished product is ensured in the long term, which results in a wide range of savings.