Optimization of droplet dispersion mixing

Motivation

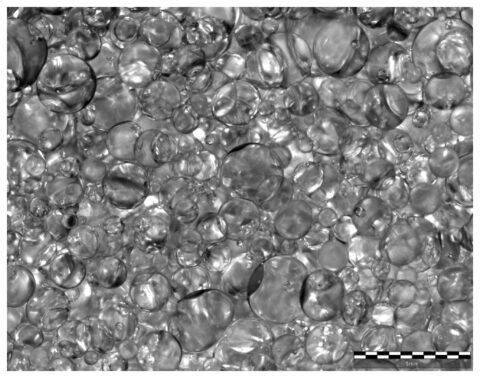

The interfacial surface area in liquid-liquid dispersion controls the mass transfer between the phases. The surface area is determined by the droplet size of the dispersed phase. A selection of impeller designs and mixing speeds is tested to study the effect of these parameters on droplet size.

Implementation

A Pixact Droplet Monitoring (PDM) system is installed on a 2-liter test reactor equipped with a side inlet. The same setup can also be used for production-scale reactors. The dispersion consists of organic solvent (50 %) and water (50 %).

Benefits

The measured droplet size distribution can be used to select an optimal impeller design and mixing speed for the production-scale process. In production scale, PDM can be used to adjust droplet size distribution by controlling mixer speed and the component feed to the reactor.

Process parameters

| Dispersion | Liquid-liquid |

| Size distribution | 50…1000µm |

| Concentration | 50-50 % |

| Temperature | 25°C |

| Pressure | Atm |