Monitoring of a flotation in water treatment facility

Motivation

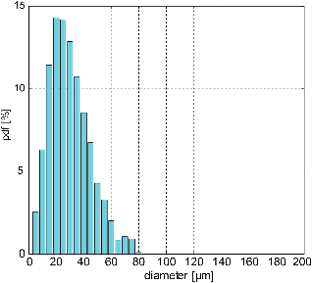

The feed and operating conditions of an industrial water treatment facility vary considerably. Disturbances in the main process are reflected in the effluent and seasonal variation of ambient temperature creates additional challenge in the operation. To optimize the flotation phase, real-time information of key process parameters, such as bubble size distribution and flocculation efficiency is needed.

Implementation

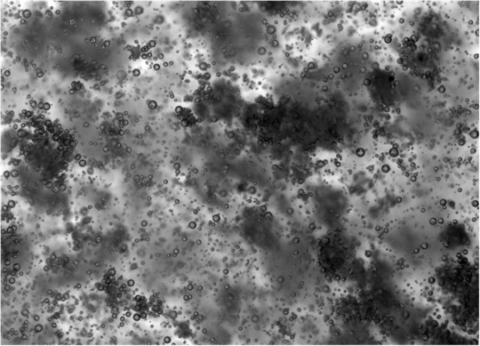

A custom Pixact Bubble Monitoring (PBM) system was developed to produce real time-measurement data from an open flotation tank. The imaging unit is submersed in two meters depth in the flotation tank to monitor the bubble and flock size distribution as the air feed, chemical dosage and other process parameters are varied.

Benefits

The effect of the mixing speed, air feed and flocculant dosage are studied to find the optimal flotation conditions for given effluent characteristics.

Process parameters

| Process | Flotation in water treatment |

| Bubble size distribution | 5µm…100µm |

| Flock size distribution | 50µm…5000µm |

| Temperature | 10-20°C |

| Pressure | Atm |