Implementation of automatic seeding

Motivation

The timing of seeding is very critical in the crystallization food ingredient products. Seeding is performed manually by the operator. Thus, there is a lot of operator dependent variation in the batchwise yield and quality.

Implementation

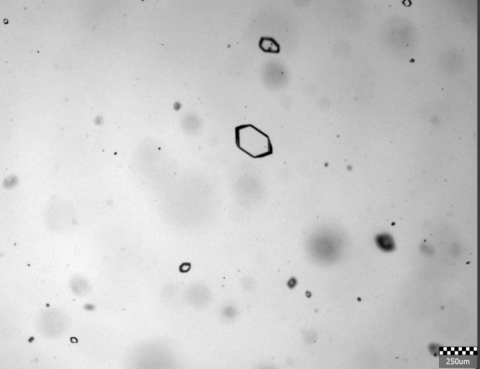

A Pixact Crystallization Monitoring (PCM) system was equipped with a special analysis module to detect spontaneous nucleation before the seeding point. The system measures the number of crystals detected per second as supersaturation is approached. When the number of crystals per second exceeds the given threshold, seeding is executed.

Benefits

With the automatic triggering of the seeding signal, variation in the seeding time is minimized. As a result, out-of-spec batches were completely eliminated in the 6-month follow-up period.

Process parameters

| Crystalline product | Food ingredient |

| Size distribution | 10…300µm |

| Solids concentration | 30 w-% |

| Temperature | 90°C |

| Pressure | Vacuum |