Analysis of fiber refining

Motivation

Refining is used to optimize stock properties (disintegration, fiber fibrillation, fiber morphology) to improve final paper or board characteristics. A lot of energy is used in refining and the control of refining process based on the measured fiber characteristics enables a huge energy saving potential.

Implementation

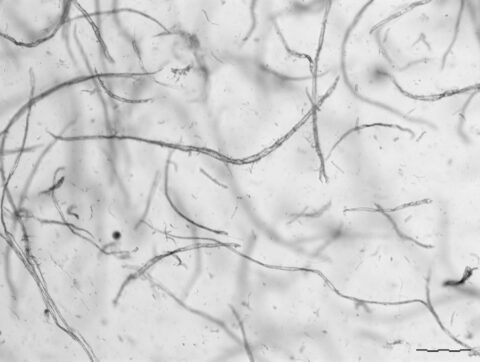

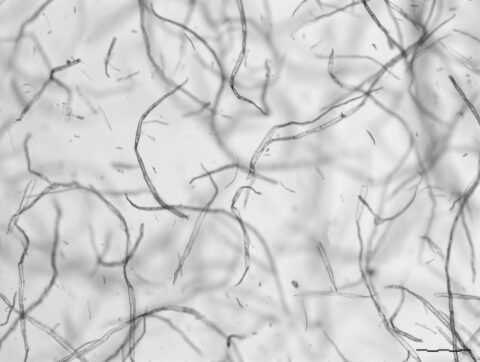

A Pixact Particle Monitoring (PPM) system equipped with an automatic dilution station is installed before and after the refiner to analyze the fiber properties online. Real-time statistics of fiber characteristics, such as fibrillation index, fiber length and width and fiber morphology (kinks and curl) is produced.

Benefits

Online measurement of the actual refining results allows optimization of the refiner gap, RPM and other parameters to save energy and prevent too heavy processing of the stock.

Process parameters

| Production process | Paper production |

| Particle size distribution | 5…3000µm |

| Solids concentration | 1-5 w-% |

| Temperature | 40°C |

| Pressure | 1-2 Bar |