Stock Impurities

Detect and analyze impurities and colors directly from the pulp suspension flow in real time

Improve pulp quality control with Pixact Stock Monitoring

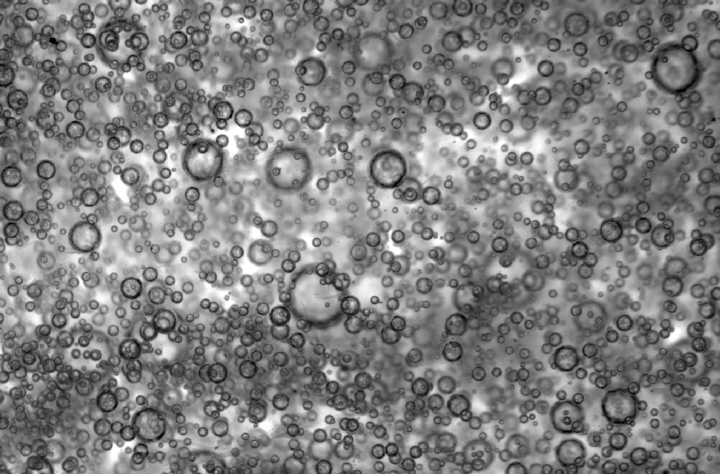

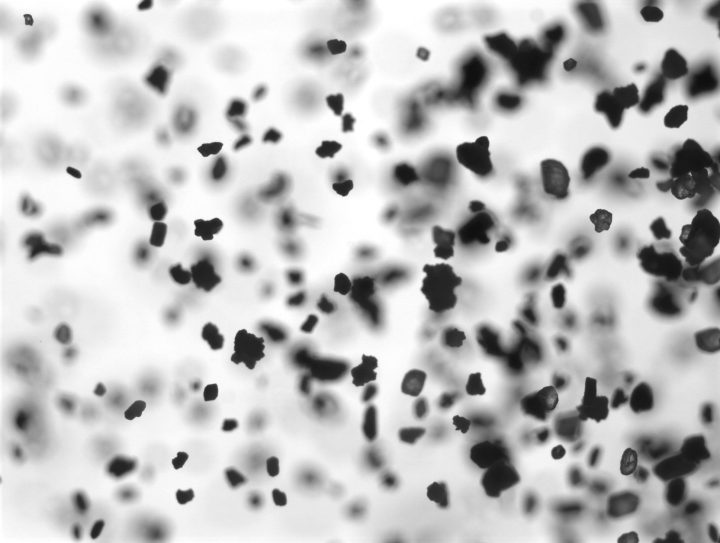

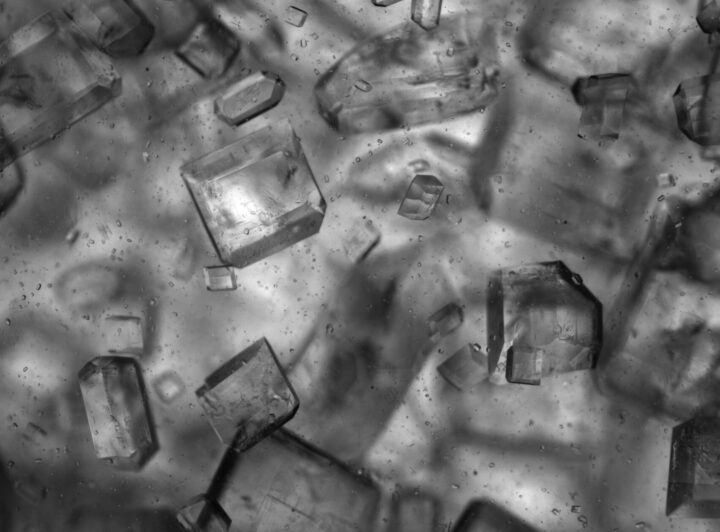

In pulp production and processing of recycled pulp, various sources of impurities are present. Uncooked components in bleached pulp and residues of ink and coating in recycled pulp may impair the pulp quality.

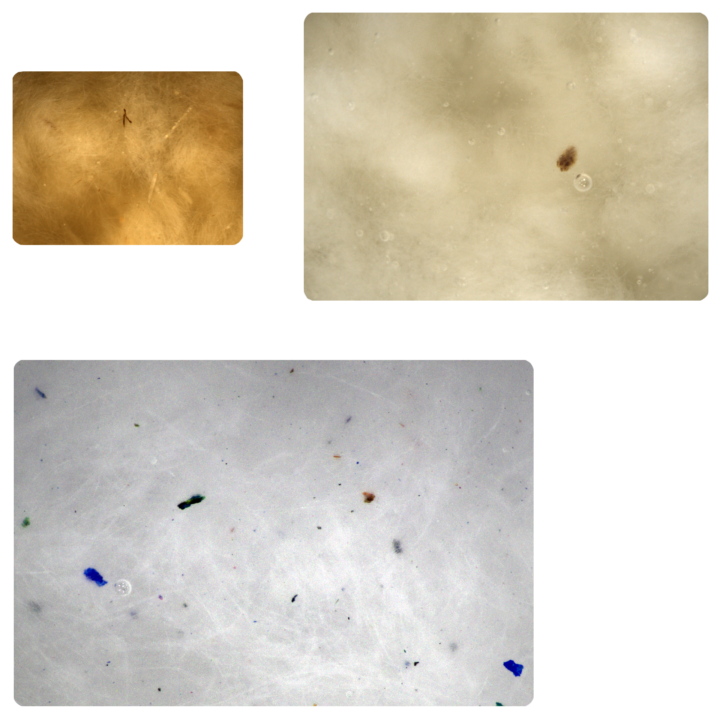

The Pixact Stock Monitoring (PSM) technology is designed for the analysis of impurities and color of flowing pulp suspension. The PSM system is installed directly on the process line as a flow-through section. Installing PSM in several locations helps tracking the origin of impurities, and corrective measures can be done in real-time. The PSM system is applicable with brown, bleached, and recycled stock. With the data provided by PSM, you can adjust process parameters to solve quality and runnability issues, and cut your operating costs and avoid costly interruptions in production.

Results

The system provides real-time measurement data without the need for preparing samples for analysis. System detects wide range of impurities, such as shives and other uncooked components, bark, soot, silica particles, rubber, resins, ink, and precipitated chemicals.

Measurement result produced by PSM include

- Number of particles, i.e. impurities (e.g. pcs/m2 or pcs/kg)

- Size (d [mm] or A [mm2]), shape and color of each particle

- Particle classification and statistics for each class separately

- Pulp color/brightness trend

Discover solutions for Stock Impurities application

Explore our advanced solutions for real-time analysis. From the Pixcell flow-through cuvette to the Pixscope probe, find the perfect product for your needs.