Solutions

A brighter picture of your process

Based on inline process microscopy

Pixact measurement systems are based on the direct optical imaging of process suspensions in pipelines, reactors, and tanks. The image acquisition is followed by image analysis with proprietary algorithms to detect dispersed phase elements, such as particles, bubbles and crystals. As a result, detailed statistics for these elements, including size, shape, velocity and color, are obtained.

Modular product platform

Our measurement solutions are built following a modular concept. The Pixact measurement systems consist of an imaging unit – a Pixscope probe or a Pixcell flow-through cuvette – and a Pixstation main unit running the Pixact measurement software. Application-specific analysis modules can be combined with any type of imaging unit.

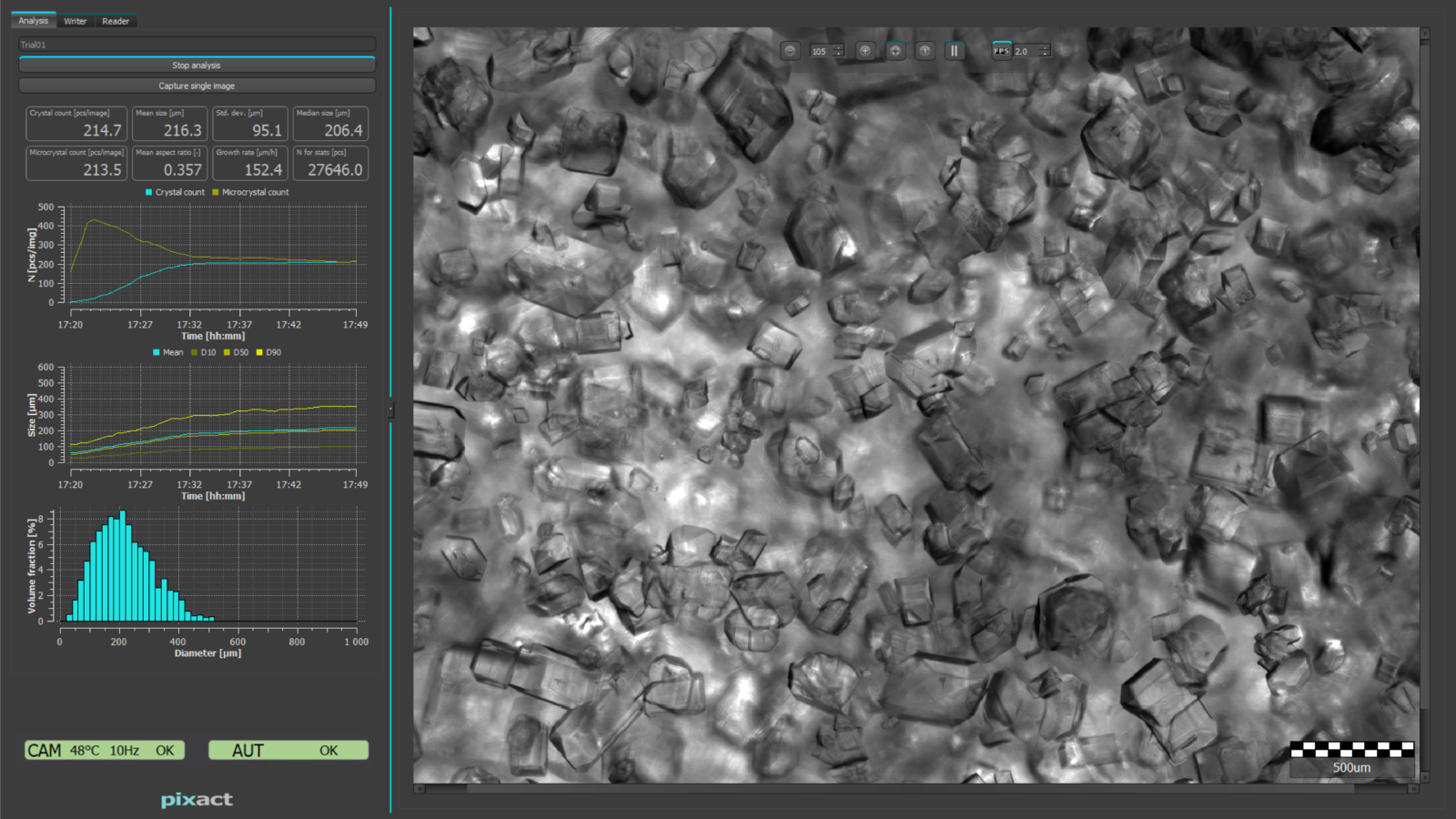

Measurement Software

Pixact Software controls the entire measurement procedure, including the hardware, data acquisition, image analysis, and results post processing. Depending on the system specification, the operation varies from a fully automated inline measurement to a manually controlled data collection and analysis. Pixact Software can be configured from a robust inline analysis software to an effective R&D tool, giving access to all required settings.

Key Features

User-friendly adjustment of imaging parameters

- Automatic camera controls to optimize the image quality in varying process conditions

- Adjustable image refresh frequency with zoom and pause features

- Image recording capabilities with time stamps for later inspection or analysis

Powerful analysis algorithms

- High-performance image analysis techniques to produce real-time quantitative measurement information from the image stream

- In-house developed image analysis modules available for several application analyses – customized analysis features on request

Flexible reporting tools

- Image data storing to internal or external hard drive

- Internal database for the measurement results

- Export results in the Microsoft Excel ®, CSV, or ASCII format

- From systems equipped with an automation interface, results can be transmitted to external data collection using OPC-UA, Pronet or another standard protocol

Imaging Units

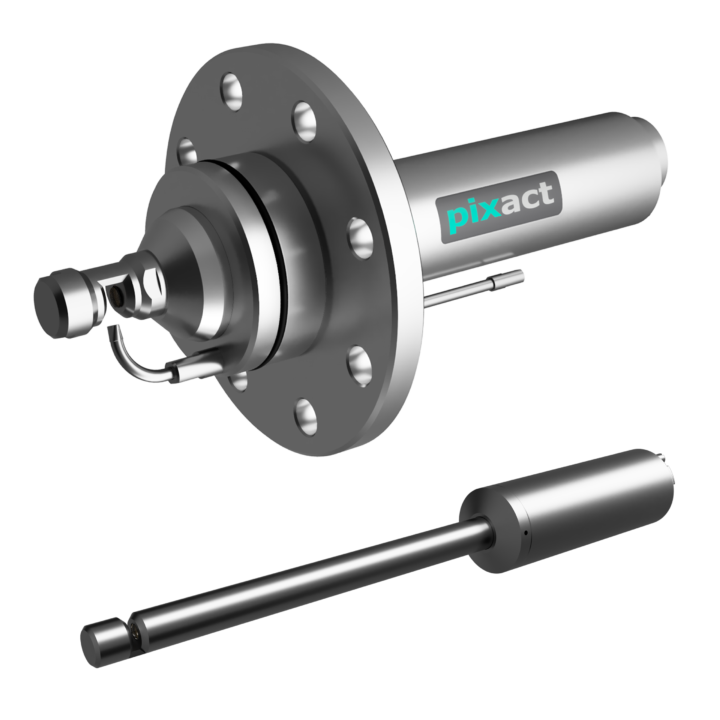

Pixscope

The Pixscope probe can be installed in reactors, vessels and tanks. The tip of the probe is submersed into the suspension. The images are captured as the suspension flows through the measurement gap in the tip using a transillumination setup. The Pixscope probe requires a DN25 or larger fitting. Custom adapters can be delivered for existing inlets.

The Pixscope probes are available in various dimensions:

- Various wet-part diameters are available, starting from 14 mm

- Length of the wet-part varies between 50-300mm

- Width of the measurement gap 3/5/10mm (fixed, not adjustable)

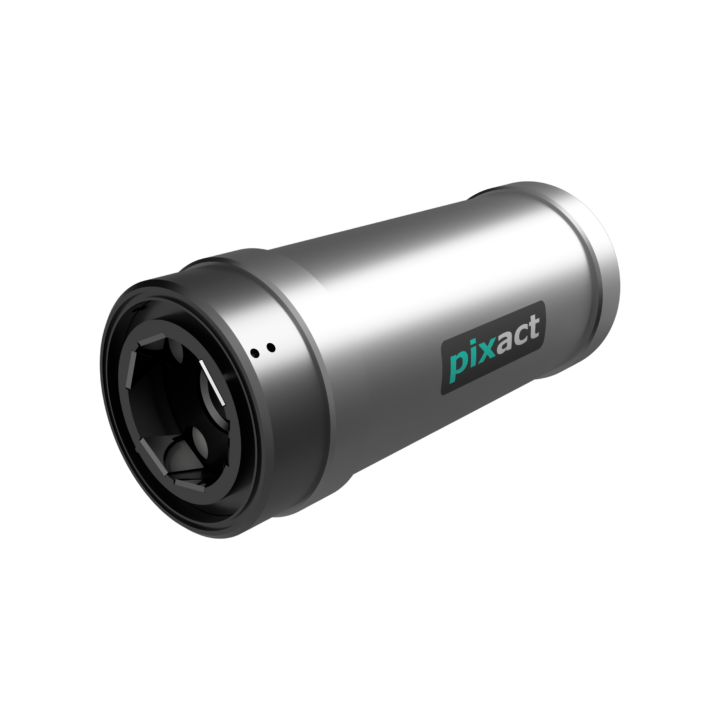

Pixcell

The Pixcell flow-through cuvette can be installed on process lines and dedicated sampling lines. The suspension is fed through the cuvette where images of the suspension are captured using transillumination.

Pixcell is available in several standard flow inlet/outlet sizes:

- DN06 (1/8″)

- DN08 (1/4″)

- DN10 (3/8″)

- DN15 (1/2″)

- DN25 (1″)

- DN50 (2″)

Custom sizes are available on request.

Pixscope SG

The Pixscope SG is a front light version of the Pixscope probe. The Pixscope SG is non-invasive, as it is installed on the sight glass of a reactor or pipeline. Thus, the probe is not in direct contact with the suspension. The images of the suspension are captured through the sight glass.

Main Units

Pixstation LAB

Pixstation LAB is a portable main unit to the Pixact measurement system. It is designed for R&D use in laboratories and pilot facilities where the measurement location may change frequently. Portability also allows the system to be shared between user groups and even different locations.

Through a flexible communication interface, signals from thermocouples and pressure sensors can be logged in the Pixact system. The system is also able to control selected stirrers and poultices enabling real-time automated process control and optimization based on measurement data of particle size, morphology and concentration.

Pixstation ONLINE

Pixstation ONLINE is the Pixact main unit for industrial inline use. It houses the measurement computer, automation gateway, power supply and all connection terminals to external systems. The cabinet can be equipped with local or remote display to view the Pixact software user interface. With IP65 level protection the cabinet can be installed in the field next to the imaging.