Particles

Analyze particle size, shape and even color directly in the process line in real time

Analyze industrial processes in real time with Pixact Particle Monitoring

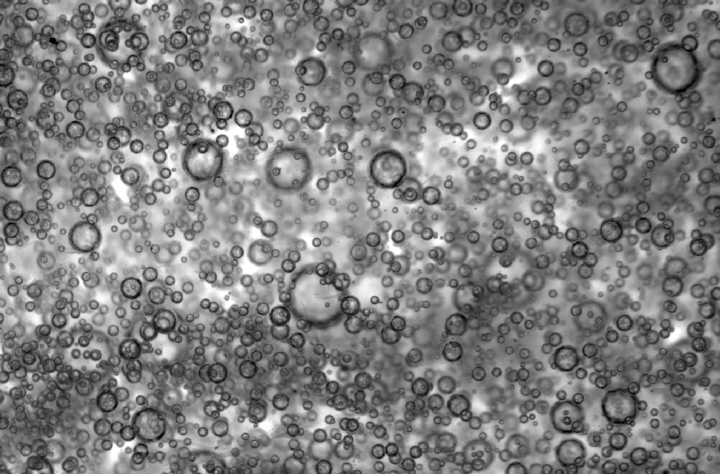

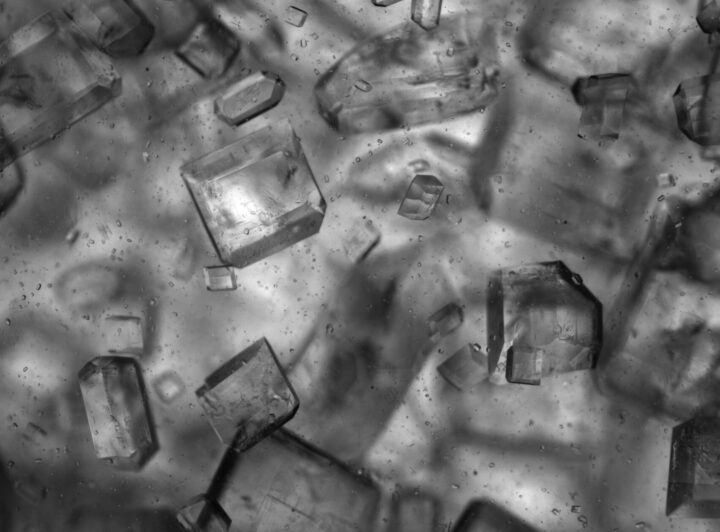

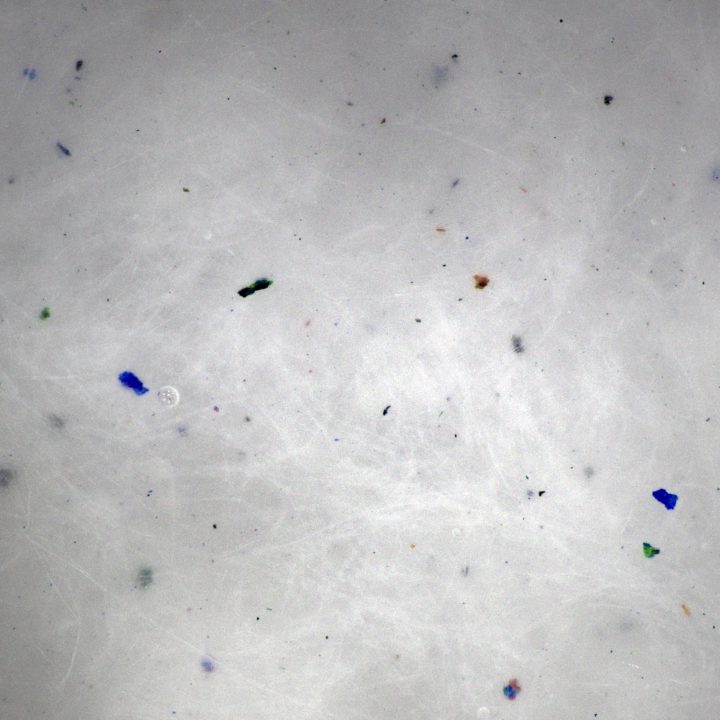

Particles are inherent in most industrial processes, either as final products or contaminants. Pixact Particle Monitoring (PPM) technology is designed for the inline analysis of particle size and morphology. PPM analyses microparticles, granules, fibers, agglomerates, flocs and more. The PPM technology combines inline process microscopy with advanced image analysis techniques. The measurement results produced by PPM help you optimize, control, and troubleshoot your process efficiently. With PPM you increase the yield and capacity of your process and minimize quality variations in the final product.

Results

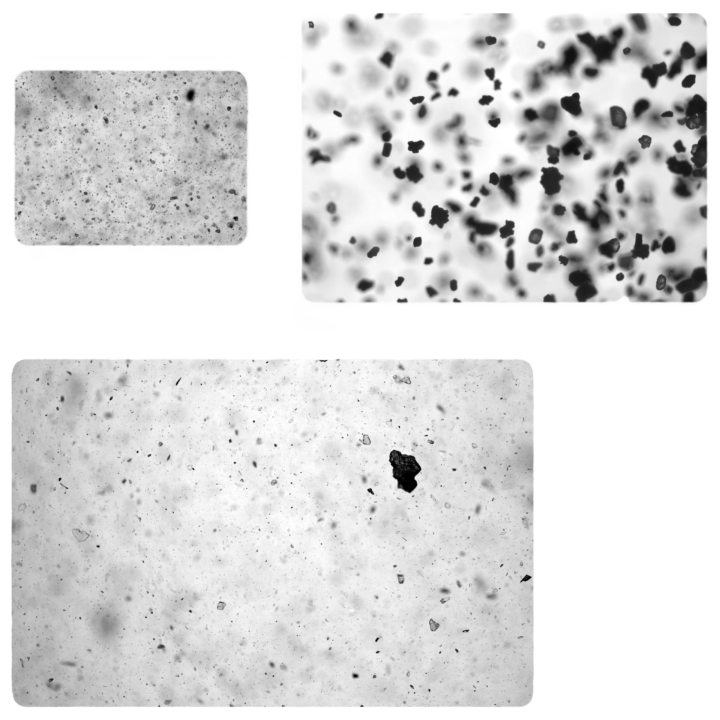

PPM provides a live camera view of the particle suspension and detailed real-time measurement data on particle characteristics, such as size distribution, morphology, and concentration.

Typically, hundreds of particles are detected in each image. This data is then used to compute size and shape distributions and related statistics, such as percentiles of cumulative distribution (D10, D50, D90, etc.). The mean particle size can be calculated as arithmetic, area (Sauter) or volume weighted value.

Measurement results produced by PPM include

- Particle diameter (based on the circular equivalent area)

- Minor & major axis length

- Particle projection area

- Number of particles in the measurement volume

Discover solutions for Particles application

Explore our advanced solutions for real-time analysis. From the Pixcell flow-through cuvette to the Pixscope probe, find the perfect product for your needs.